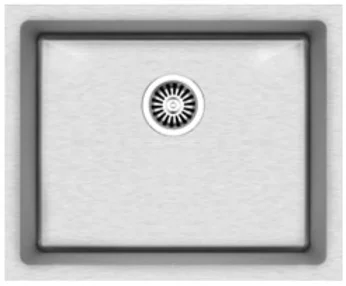

BP Single Bowl 740mm Gun Metal

€440.00

Facebook

WhatsApp

Email

Print

Description

COLOUR:

Stainless Steel

MATERIAL:

Stainless Steel 316

TYPE: Under/Overmount Kitchen Sinks

Under/Overmount Kitchen Sinks

Marine Grade 316 Stainless Steel Kitchen Sinks

- 1.2mm Thick.

- Colour: Gun Metal (PVD)

- Radius 10 Corners; This is the ideal Curve in the corner of sinks to avoid dirt being clogged up making it difficult to clean.

- Supplied with sound reducing pads.

- Can Be installed Both Top Mount and Under Mount

- Round Strainers with Overflow Pipe.

Advantages of Grade 316 Stainless Steel VS 304 Stainless Steel

- Stainless steel grades 316 and 304 are both widely used in various industries due to their corrosion resistance, durability, and versatility. However, they have different compositions and properties, leading to distinct advantages for each. Here are some of the advantages of grade 316 over grade 304:

- Increased Corrosion Resistance: Grade 316 stainless steel contains molybdenum, which enhances its resistance to corrosion, particularly in harsh environments such as marine or chloride-rich settings. This makes it more suitable for applications where corrosion is a significant concern compared to grade 304.

- Better Resistance to Chloride Pitting and Crevice Corrosion: The presence of molybdenum in grade 316 stainless steel improves its resistance to chloride-induced corrosion, including pitting and crevice corrosion. This makes it ideal for use in coastal areas, near saltwater, or in chemical processing environments where chloride exposure is common.

- Higher Temperature Resistance: Grade 316 stainless steel has better high-temperature resistance compared to grade 304. It can withstand higher temperatures without significant degradation or loss of mechanical properties, making it suitable for applications involving elevated temperatures or thermal cycling.

- Improved Strength and Ductility: While both grades exhibit excellent mechanical properties, grade 316 stainless steel typically has slightly higher tensile strength and yield strength compared to grade 304. Additionally, grade 316 offers better ductility and toughness, which can be advantageous in applications requiring forming or fabrication.

- Suitability for Surgical and Medical Applications: Due to its superior corrosion resistance and biocompatibility, grade 316 stainless steel is often preferred for medical and surgical instruments, implants, and equipment. It meets stringent regulatory requirements and offers excellent performance in medical environments.

- Hygiene and Sanitary Properties: Grade 316 stainless steel is highly resistant to corrosion and staining, making it ideal for use in food processing, pharmaceutical, and sanitary applications. Its smooth surface finish and ease of cleaning contribute to better hygiene and reduced risk of contamination.

Advantages of (PVD) Physical Vapor Deposition

- Hardness and Wear Resistance: PVD coatings are known for their exceptional hardness, often surpassing that of traditional coatings such as electroplating. This makes them highly resistant to wear, abrasion, and surface damage, extending the lifespan of components and tools in applications subject to mechanical stress.

- Improved Surface Properties: PVD coatings can significantly enhance the surface properties of materials. They can provide surfaces with increased smoothness, reduced friction, and improved release properties, making them ideal for applications where sliding or contact is involved, such as cutting tools, Kitchen Sinks, Bathroom Faucets and bearings.

- Chemical Resistance: Many PVD coatings exhibit excellent chemical resistance, protecting the underlying substrate from corrosion, oxidation, and chemical attack. This makes them valuable for applications in harsh environments or industries where exposure to corrosive agents is common, such as automotive, aerospace, and chemical processing.

- Temperature Resistance: PVD coatings can withstand high temperatures without degrading, making them suitable for applications involving elevated temperatures, such as cutting and machining operations, where heat generation can be significant.

- Decorative and Aesthetic Appeal: PVD coatings can be tailored to produce a wide range of colors and finishes, offering decorative and aesthetic appeal in addition to their functional properties. This makes them popular for decorative applications in jewelry, watches, architectural hardware, and consumer electronics.

- Environmentally Friendly: Compared to traditional coating methods such as electroplating, PVD processes are generally more environmentally friendly. They typically produce fewer hazardous by-products and waste, making them a more sustainable choice for coating applications.

- Uniform and Conformal Coating: PVD coatings provide uniform thickness and coverage over complex geometries and irregular surfaces, ensuring consistent performance across the entire coated component. This capability is particularly advantageous for coating intricate shapes and parts with tight tolerances.

- Tailored Properties: PVD coatings offer flexibility in terms of composition and structure, allowing engineers to tailor their properties to specific application requirements. This customization capability enables the design of coatings with optimized performance characteristics, such as adhesion, hardness, friction, and optical properties.

- Overall, the advantages and strengths of PVD coatings make them highly versatile and desirable for a wide range of applications across various industries, including automotive, aerospace, tooling, electronics, medical devices, and more.